- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why is the Emergency Stop Button so important?

2025-09-10

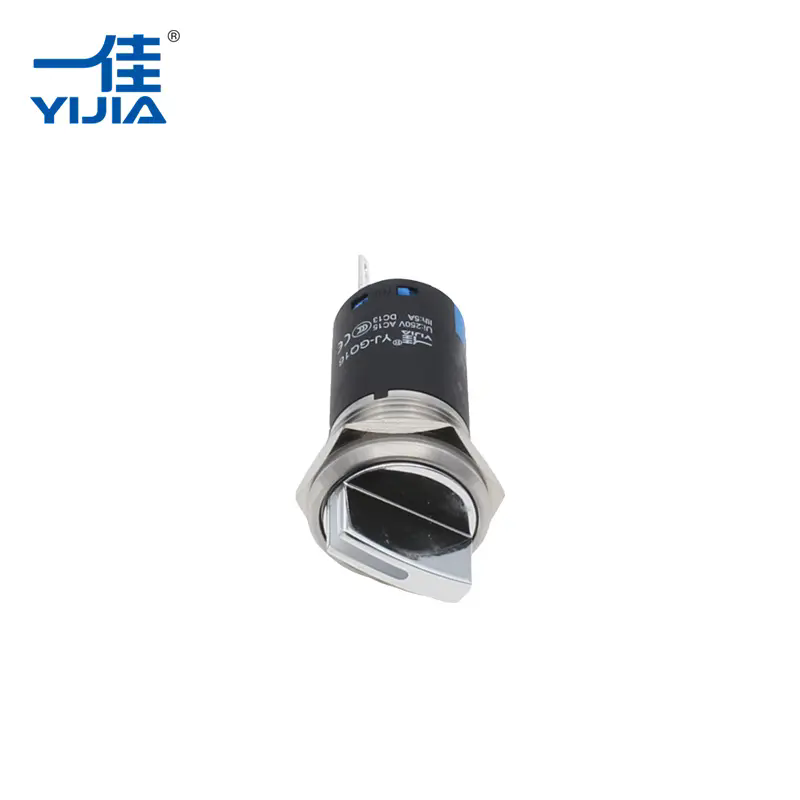

In industrial environments, machinery and equipment operate at high speeds and draw enormous power. Unexpected hazards such as mechanical failure, human error, or process deviations can escalate into life-threatening incidents in seconds. The Emergency Stop Button is the last line of defense. When pressed, it overrides all operations and instantly stops the machine, protecting personnel, preventing expensive equipment damage, and minimizing production downtime. YIJIA specializes in the design of these critical safety components. Let's take a look at this important safety component.

Core Features

Reliable Locking Mechanism

Once activated, the button remains locked in the "off" position until manually reset, ensuring the equipment remains stationary during troubleshooting.

Instantaneous Response

Contacts open within milliseconds, irreversibly disconnecting power.

High Visibility and Ease of Use

Emergency Stop Buttons must be easily visible and easily identified in an emergency.

Rugged

Designed to withstand over 1 million mechanical cycles, they can withstand harsh industrial environments.

Easy Installation and Compatibility

Quick-release mounting and a variety of sizes ensure seamless integration.

Technical Specifications

Electrical Ratings:

Voltage: 24V DC to 600V AC

Current: 10A (resistive) / 6A (inductive)

Contact Type: Normally Closed (NC) for fail-safe operation

Environmental Compatibility:

Temperature Range: -25°C to +70°C

Ingress Protection: IP67 (dustproof/waterproof)

Safety Certifications: ISO 13850, IEC 60947-5-5

Mechanical Specifications:

Operating Force: 50–70N

Reset Method: Rotary Release or Key Release

Mounting Method: Panel Mount, Cable Drive, or Flush Mount

| Type | Material Used | Best Suited For |

| Metal | Stainless steel/IP65 housing | Heavy machinery, high-vibration environments |

| Plastic | Self-extinguishing PBT | Chemical labs, wet/corrosive areas |

FAQ

Q1: How does the Emergency Stop Button prevent workplace injuries?

A1: Emergency stop devices provide an easily accessible point to immediately disconnect power to a machine, preventing hazardous movement that could cause crushing, entanglement, or electric shock. According to the U.S. Occupational Safety and Health Administration, 70% of industrial fatalities are related to accidental equipment startup. Emergency Stop Buttons can reduce this risk.

Q2: Why is a "lockout" feature necessary in the design of an emergency stop device?

A2: The lockout feature ensures that the equipment remains offline until intentionally reset. If the button automatically resets, the machine could restart during a rescue attempt, exacerbating the emergency situation. YIJIA's rotary release mechanism prevents accidental reactivation and complies with ISO 13850.

Q3: Does the Emergency Stop Button impact production efficiency?

A3: Yes, it definitely does. While stopping a machine interrupts workflow, a fast-responding emergency stop device can minimize the damage. A manufacturing study found that factories using ISO-certified emergency stop devices experienced a 50% reduction in downtime due to faster troubleshooting and fewer equipment repairs compared to non-compliant alternatives.

Related News

- What Makes a Metal Push Button Switch the Best Choice for Modern Electrical Control Systems?

- What are the advantages of using a Metal Selector Switch?

- How does the Customizable Push Button Switch unlock endless possibilities?

- Unlock Superior Control: The Definitive Guide to Industrial Key Switches

- Is the Switch Emergency Protective Cover necessary?

- What are the categories of Plastic Push Button Switch?