- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How Does a Plastic Selector Switch Improve Industrial Control Systems?

Plastic Selector Switch is a core component in industrial control systems — widely used in machinery, automation panels, and human‑machine interfaces. In this comprehensive guide, we explore the term, related keyword variations, applications, advantages, disadvantages, FAQs, and best practices for selecting the right switch for your project.

Table of Contents

- What is a Plastic Selector Switch?

- Why Choose a Plastic Selector Switch?

- What Are the Different Types of Selector Switches?

- What Are the Pros & Cons?

- Where Are These Switches Used?

- What Features Should You Look For?

- How to Install Them Safely?

- FAQs Related to Plastic Selector Switch and Variations

- References

What Is a Plastic Selector Switch?

A Plastic Selector Switch is a manually operated electrical switch that allows users to select different electrical circuits or machine states (e.g., ON/OFF, AUTO/MANUAL) by rotating a plastic handle or knob. These switches are widely used in industrial control panels due to their affordability, ease of installation, and ergonomic design.

What Does “Industrial Plastic Selector Switch” Mean?

“Industrial Plastic Selector Switch” refers specifically to selector switches designed for industrial environments — rugged, reliable, and compliant with safety standards.

What Is a “Panel Mount Plastic Selector Switch”?

“Panel Mount Plastic Selector Switch” describes selector switches mounted on control panels to allow operator interaction with machine processes or control logic without opening enclosures.

Why Choose a Plastic Selector Switch?

Choosing a plastic selector switch balances cost, performance, and durability. While metal switches are available, plastic options offer lightweight design, corrosion resistance, and flexibility for many applications.

- Cost‑effective alternative to metal‑bodied switches

- Reduced risk of corrosion in humid environments

- Quick replacement and modular design

What Are the Different Types of Selector Switches?

What Is a 2‑Position Selector Switch?

A 2‑position selector switch typically alternates between two states: ON/OFF or OPEN/CLOSE.

What Is a 3‑Position Selector Switch?

A 3‑position selector switch can cycle through three positions — often used for OFF, ON, and a middle SAFE or NEUTRAL position.

What Is a Momentary Plastic Selector Switch?

A momentary switch returns to its original position when released, frequently used in machine start commands with safety hold‑off requirements.

What Are the Pros & Cons?

| Feature | Pros | Cons |

|---|---|---|

| Plastic Housing | Lightweight, corrosion‑resistant | Less impact‑resistant than metal |

| Cost | Generally lower than metal switches | May not last as long in harsh environments |

| Installation | Easy with panel mounts | Requires correct sealing for water/dust |

| Maintenance | Simple to replace modular parts | Plastic parts may wear faster under heavy use |

Where Are These Switches Used?

Plastic selector switches are present in a wide variety of machines and systems, including:

- Industrial control panels (e.g., conveyor systems, motor starters)

- Automation systems for manufacturing lines

- HVAC control interfaces

- Packaging machines

- Elevator control panels

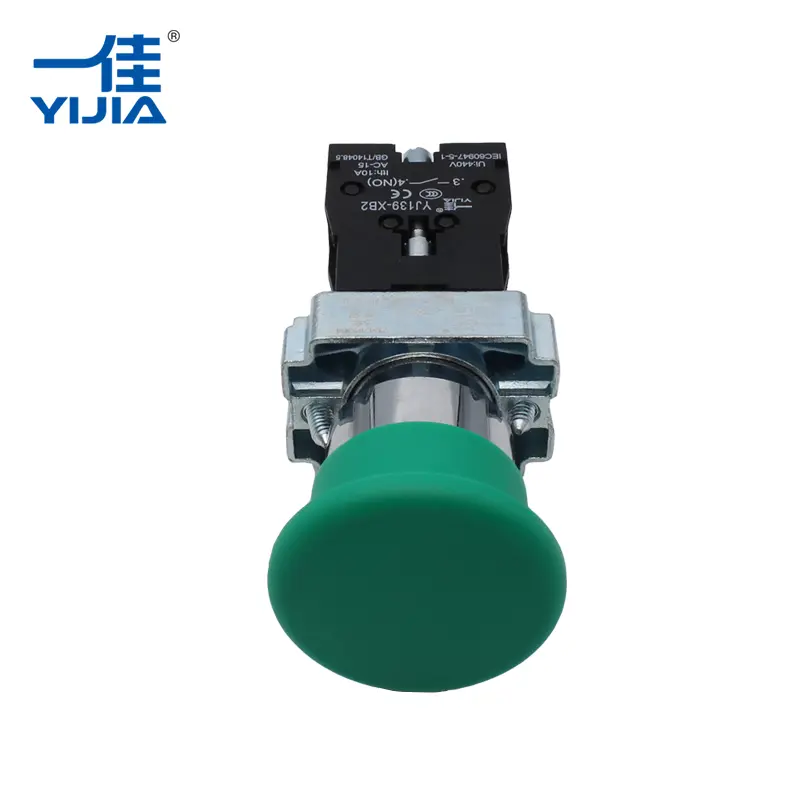

Companies such as Yijia Industrial Electric Co., Ltd. produce robust selector switches tailored for industrial control systems that meet global quality standards.

What Features Should You Look For?

- Durability Rating: Look for IP ratings (e.g., IP65) if exposure to dust/water is expected.

- Actuator Style: Rotary knob vs. flat paddle — select based on ergonomic needs.

- Electrical Rating: Confirm voltage and current ratings for your application.

- Mounting Size: Standard panel mount diameters ensure easy replacements.

- Safety Certification: UL, CE compliance adds confidence for industrial installations.

How to Install Them Safely?

Installing a plastic selector switch involves:

- Turning off all electrical power to the panel.

- Drilling or using the correct panel cutout template.

- Inserting the switch and tightening with specified torque.

- Connecting the wiring — follow the wiring diagram exactly.

- Testing operation before returning to full system power.

Always refer to manufacturer instructions — for example, those from Yijia Industrial Electric Co., Ltd. — to avoid voiding warranties or violating safety standards.

FAQs Related to Plastic Selector Switch and Variations

Q: What differentiates a plastic selector switch from a metal one?

A: A plastic selector switch uses plastic housings and actuators, which make it lighter and more corrosion‑resistant. Metal switches are typically stronger under impact but cost more and may corrode over time in certain environments.

Q: Can a plastic selector switch be used outdoors?

A: It can be used outdoors if it has a proper IP rating such as IP65 or higher, protecting against dust and low‑pressure water jets. Always verify the manufacturer’s specifications.

Q: How do I choose between a 2‑position and 3‑position selector switch?

A: Choose based on function. If you only need a simple ON/OFF function, a 2‑position switch suffices. A 3‑position switch adds flexibility (e.g., OFF/NEUTRAL/ON) for complex control logic.

Q: What does “Panel Mount” mean for selector switches?

A: “Panel Mount” refers to how the selector switch is installed — it’s mounted through a hole in a control panel so operators can access it externally while the electrical connections remain inside.

Q: Are industrial plastic selector switches safe?

A: Yes, when used within their rated electrical loads and installed per standards. Safety certifications like UL and CE signify compliance with rigorous testing.

Q: How long do plastic selector switches last?

A: Lifespan depends on usage, environment, and build quality. High‑quality models, especially from reputable suppliers like Yijia Industrial Electric Co., Ltd., can last many years in industrial settings.

Q: What are common faults in selector switches?

A: Common issues include contact wear, mechanical sticking, and dust ingress. Regular inspection and maintenance help prolong service life.

Q: Why is correct electrical rating important?

A: Using a switch beyond its rating can cause overheating, contact welding, or safety hazards. Always match voltage and current ratings to your application.

References

- Industry Standards for Selector Switches — Electrical Control Components (IEC/UL)

- Selector Switch Installation & Maintenance Guidelines — Manufacturer Technical Sheets

- Control Panel Design Best Practices — Automation World Publications

Contact Us: If you’re looking for reliable, high‑quality selector switches for your machinery or panel builds, reach out to Yijia Industrial Electric Co., Ltd. — our experts are ready to help you choose the right components for your application. Contact us today!

Related News

- What Is a Metal Selector Switch and Why Does It Matter in Industrial Control Systems?

- What Customizable Push Button Switch Can Do for Industrial Control Systems?

- What Is a Red Emergency Button and Why Is It Critical for Industrial Safety?

- What Makes a Metal Push Button Switch the Best Choice for Modern Electrical Control Systems?

- What are the advantages of using a Metal Selector Switch?

- How does the Customizable Push Button Switch unlock endless possibilities?

Leave me a message