- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What are the usage scenarios of Selector Switch?

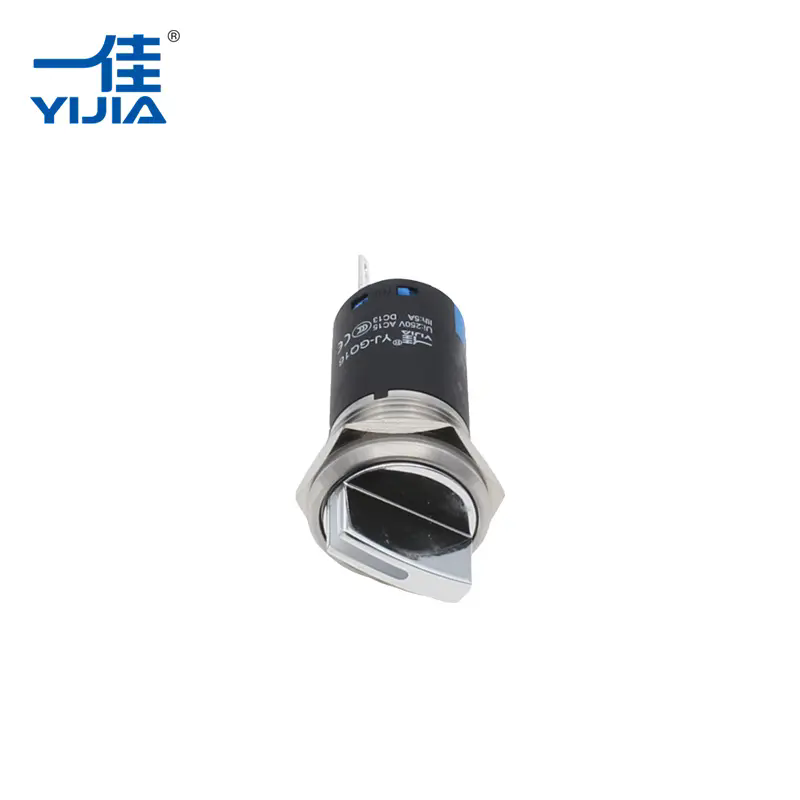

Selector switches are an essential component of industrial control systems. As durable mechanical interfaces for circuit selection, mode switching, and operational control, they play a critical role in environments requiring the utmost reliability and precision. Yijia, with 20 years of engineering experience in pushbutton and switch manufacturing, explains their application scenarios.

Selector Switch Core Specifications

Actuator: Short handle, long handle, key-operated, illuminated/non-illuminated

Contact Material: Silver alloy (low resistance, high conductivity)

Casing: Engineering plastic (UL94 V-0 flame retardant) and brass terminals (corrosion-resistant)

Electrical Rating: 10A/250V AC, 5A/30V DC

Mechanical Lifespan: ≥100,000 cycles

IP Rating: IP65 (dustproof and water-jet-proof)

Selector Switch Application Scenarios

1. Industrial Automation Control Panels

Function: Mode selection (auto/manual/reset) for PLCs, motor starters, and conveyor systems.

For example: switching a production line between "high speed," "maintenance," and "emergency stop" modes. Recommended Type: 30mm three-position key switch (prevents unauthorized access).

2. Machinery Operation and Safety

Function: Equipment status control (on/off/jog) for CNC machine tools, pumps, and compressors.

For example: selecting "forward," "reverse," or "neutral" on heavy drilling equipment.

Recommended Type: 22mm illuminated long-handle switch (clearly visible even in low-light areas).

3. Energy Management System

Function: Circuit routing in power distribution units, generators, and solar inverters.

For example: Switching loads between "grid," "generator," and "battery" power sources.

Recommended Type: Three-position selector switch with silver contacts (minimizes arcing under high currents).

4. Transportation and Signaling Systems

Function: Signal path switching in railway signals, traffic lights, and aviation control.

For example: Selecting "primary," "secondary," or "off" on railway track switches.

Recommended Type: IP67-rated tactile feedback switch (reliable operation even in inclement weather).

Installation Dimensions

| Mounting Hole Size | Actuator Length | Positions | Contact Configuration |

| 16mm | 15mm | 2-Pos | 1NO/1NC |

| 22mm | 25mm | 2/3-Pos | 2NO/2NC |

| 30mm | 40mm | 3-Pos | 3NO/3NC |

FAQs

Q: What are the main differences between two-position and three-position selector switches?

A: A two-position switch alternates between two circuits (e.g., on/off), while a three-position switch adds a neutral or alternate state (e.g., auto/off/manual). The latter enables multi-mode control, which is crucial for complex machinery.

Q: How are selector switches used in hazardous environments?

A: In explosive or dusty environments (e.g., chemical plants), key-operated or sealed IP68 switches prevent accidental activation. They are used to isolate equipment during maintenance without removing power to the entire system.

Q: How are selector switches used compared to pushbuttons?

A: Selector switches maintain their state (e.g., remain in the "on" position) and are ideal for mode selection. Pushbuttons are momentary (e.g., a "start" button triggers a single action). Selector switches are used for permanent settings, while pushbuttons are used for immediate commands.

Related News

- What Makes a Metal Push Button Switch the Best Choice for Modern Electrical Control Systems?

- What are the advantages of using a Metal Selector Switch?

- How does the Customizable Push Button Switch unlock endless possibilities?

- Unlock Superior Control: The Definitive Guide to Industrial Key Switches

- Is the Switch Emergency Protective Cover necessary?

- What are the categories of Plastic Push Button Switch?

Leave me a message